Services

Engineering and Technical Services

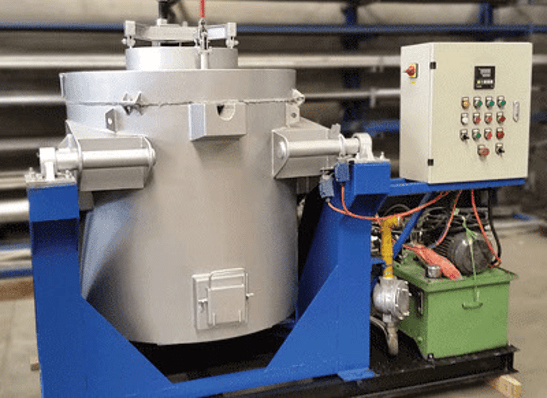

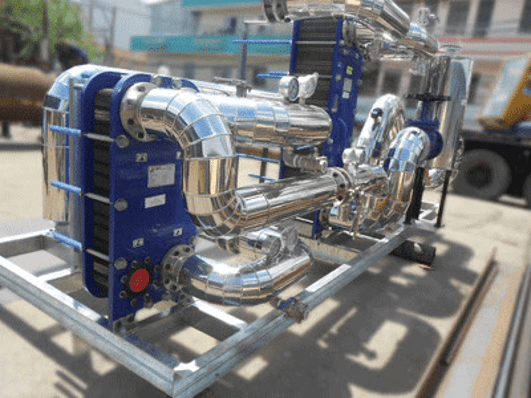

Heat Systems offer a range of engineering and technical services for all types of thermal processing equipment such as rotary kilns, elution heaters, furnaces, etc. Our services include:

- Management Services;

- Consulting Engineering;

- Planning/Front End Engineering and Design; and

- Equipment Assessment.

Heat Systems engineers and service technicians are available any time of the day or night, to discuss your specific process and thermal equipment needs. In the case of critical equipment failure or equipment downtime, our engineers and service technicians are prepared to travel to site and evaluate your needs. We will work with your team to minimise downtime and assist you with developing preventative maintenance strategies that will limit any unexpected downtime in the future.

Never let it be said that Heat Systems does not take pride in its manufactured equipment or spares. Our interest does not cease after a sale, in fact that is just the first step in developing an ongoing relationship with your team, your process and your site. The people who are involved in the construction and design of our thermal processing equipment are the same people who service and maintain it. Our focus is to nurture a relationship with our customers that will last beyond the life of our equipment.

We offer customised service contracts to ensure that you limit any unnecessary downtime of your equipment. Heat Systems technicians will service the equipment and provide you with a detailed report at the end of every visit. These visits can be pre-planned in a service contract or organised as and when required. Furthermore, we can fabricate, procure and deliver the essential equipment spare parts in a timely and cost-effective manner.

Heat Systems technicians can service, maintain and provide spare parts for all equipment made by the following manufacturers:

- Ansac;

- Thermic;

- Jostek;

- Armstrong Holland;

- Nutec Bickly;

- Edwards;

- Metso (Carbon Regeneration Kilns only);

- Kemix;

- Furnace Industries

- …. and many others

On Site Services

EQUIPMENT ASSESSMENT

It is always good practice to have an independent assessment of your thermal processing equipment when you are considering upgrading it, servicing it or de-commissioning it. Our team of service technicians and engineers have extensive experience in most commercial, industrial and mining applications and can provide you with valuable insight into the overall health of your industrial heating equipment.

Prior to making any commercial decisions on the current and future use of any asset, Heat Systems can provide you with:

- A comprehensive asset assessment; and

- A detailed investment breakdown on asset repair or modification

Preventative Maintenance Management

Heat Systems also offer customised service contracts to ensure that you limit any unnecessary downtime to your equipment. Our team of technicians will service the equipment and within a fortnight of conducting the service, provide you with a detailed report comprising of an initial asset assessment and what was achieved during the site visit.

Additionally, our senior technicians can come to site to sit with your maintenance team and work with them to put together both a PM plan as well as the PM activities. These activities will provide you with the confidence that so long as the equipment is maintained to the PM schedule, there will be less chance of any unexpected downtime.

Equipment Repair and Servicing

As not everyone can be experts in everything, our technicians can come to your site and work with your maintenance team to repair and service any of your kilns or other thermal processing equipment (and other items if you need us to!).

Whilst assisting and managing the equipment service, our technicians are happy to answer any questions and educate your maintenance team on how to service and maintain the mechanical aspects of the item. Any electrical and burner related issues however should always be referred to Heat Systems personnel to assist you with.

.

Operator and Maintenance Training

Training operations and maintenance staff on each unique item of your process can not only bridge the knowledge gap on how one OEM differs from another when it comes to similar machinery, but it also helps with effective troubleshooting any faults.

As the equipment operators are more often the first responders when it comes to equipment faults, providing them with the knowledge to troubleshoot these can save valuable time and resources. Additional and more in depth troubleshooting and fault resolution training can be provided to the maintenance team so that there is little reason to involve the OEM in this process.

Finally, this training can also provide additional benefits by allowing the operators and maintenance team to identify additional process improvements with the equipment and process itself. These improvements can lead to cost savings through better resource utilisation, greater process efficiency and less equipment downtime.

Spare Parts Supply

Heat Systems is uniquely placed to be able to supply both off the shelf and fabricated spares for a variety of equipment. Contact us today to see how we can assist you with both cost effective and timely supply of essential spare parts.

- We service and maintain ALL types of thermal equipment from any manufacturer and of any fuel type.

- We commission ANY make of new equipment as per the manufacturer’s recommendations.

- We help to improve operating efficiency and reliability of all makes of kilns and other thermal equipment.

- We commonly receive requests to service a wide range of equipment from suppliers such as RCR Tomlinson, BoilerTech, TPE, Thermic, Edwards, Metso, Consep, Ansac, Kemix and Furnace Industries.

- We specialise in problem solving and assisting in upgrading and improving older equipment.

- We source recommended and/or alternative quality spares at competitive prices, often with shorter lead times than our competitors for all makes of equipment.

- We provide remote technical support and our technicians are available to conduct site visits within short lead times.